Do you wonder if you should switch to digital pressure gauges for your industrial/commercial applications? Going digital has become the trend in a variety of industries and for a good reason. If you haven’t made the switch yet, here’s why you should consider upgrading all your analog pressure gauges to more reliable digital models.

1. Digital Is Easier to Read

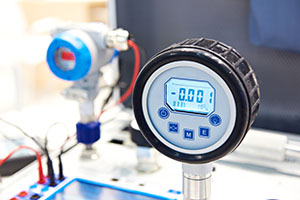

How quickly are you able to read your current gauges? If you want easy-to-read displays, digital is the way to go. Digital displays are clearer than analog, and many models even come with a bright backlight. No matter if it’s dark or hazy out, you can read digital displays with ease, reducing the risk of user error.

2. Calibrate with Precision

Proper calibration is of the utmost importance if you want accurate readings. Digital gauges have a reputation for staying calibrated much longer than analog models. Best of all, these modern gauges use a complex software system to handle all calibrations. You can trust a digital gauge to provide more reliable, precise readings.

3. Highly Durable Gauges

What good is a pressure gauge if it can’t withstand an extreme environment? Digital pressure gauges are highly durable and long-lasting. Most models feature a heavy-duty aluminum or stainless-steel body. These casings are capable of withstanding powerful vibrations—you don’t have to worry about cracking. Even in unstable temperatures or hazardous conditions, you can trust your digital device to continue working like new.

Although you will always need a power source to run a digital pressure gauge, the advantages outweigh those of similar analog models. W.P. Law, Inc. can help you find the right gauges for your business needs. Contact us to learn why digital pressure gauges are the best choice for your industrial/commercial applications.