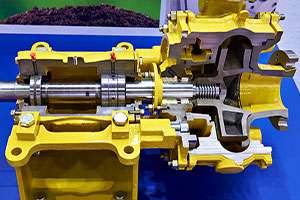

On the hunt for the perfect industrial pump? Choosing the right pump and pipe supplies is critical to the success of your company’s industrial fluid handling. Your operation has unique needs, and the right pump will have the specifications and features to streamline even the most complex fluid handling tasks.

Today’s industrial pumps utilize the latest in technology to facilitate more efficiency in your systems and operations. But it’s not always easy to know which pump is ideal for your situation. Keep reading to get the details you need to make the best choice for your industrial company.

Let the Experts Assess Your Industrial Pump Needs

Perhaps the easiest way to identify the industrial pump your business needs is to turn to trusted experts. Professional industrial pump specialists have in-depth knowledge and experience and can assess your company’s unique fluid handling needs. They don’t provide cookie-cutter solutions. Instead, they customize industrial pump design, so you have all the features you need and nothing you don’t!

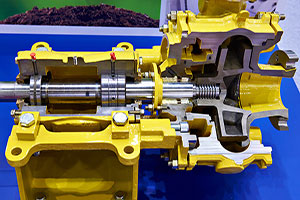

The Perfect Pump Begins with the Right Pump Supplier

Not all pump suppliers specialize in the unique needs of industrial companies. That’s why it’s essential to find a supplier who can connect you with precisely what you need to make your operations successful. In your search for a pump supplier, don’t be afraid to ask them questions about their background, qualifications, and experience with industrial pumps. Search for a company with excellent customer reviews and a proven track record of success serving local industrial companies.

Let the team at WP Law, Inc. help you find the perfect industrial pump for your company. Connect with us online now to get started!